Battery Backup Sump Pump Guide: How to Protect Your Basement from Flooding and Power Outages

This battery back up sump pump guide helps New Jersey homeowners choose the best backup system to prevent flooding and power outage damage

A battery backup sump pump is a secondary pump and power system that keeps your basement dry when the primary sump pump fails or the power goes out, protecting against costly water damage and mold. This guide explains how battery backup sump pump systems work, why they matter for flood prevention, and how to choose the right battery chemistry, capacity, and monitoring features for your home. Homeowners will learn the common failure modes of primary pumps, how to estimate run-time using amp–hours (AH) and gallons–per–hour (GPH) metrics, and practical maintenance and troubleshooting steps to extend system life. The article also compares deep–cycle wet cell, AGM, and lithium (LiFePO4) options, presents realistic cost and ROI ranges, and outlines installation trade–offs between DIY and professional service. Read on to understand trigger mechanisms, smart monitoring options, environmental disposal considerations, and concrete checklists you can use to evaluate and maintain a backup system that fits your basement and risk profile.

Battery Backup Sump Pump: Complete Guide to Flood & Outage Prevention

A battery backup sump pump is essential because it provides reliable operation during the two most common failure scenarios: primary pump mechanical failure and electrical power outages during storms. When the float switch or motor on the primary pump jams, or when utility power is cut during heavy rainfall, a backup battery system detects rising water and powers a secondary pump to remove inflow until normal service resumes. Installing backup greatly reduces the chance of water pooling, structural damage, and mold growth; understanding those failure causes helps prioritize protective measures for at–risk basements. The next subsection describes the mechanical and electrical failure modes that most often leave homeowners vulnerable.

What Causes Primary Sump Pump Failures and Basement Flooding?

Primary sump pumps fail for a handful of predictable reasons that homeowners can inspect and mitigate. Common causes include age and motor burnout, clogged intakes or impellers from debris, float switch jamming or misalignment, and electrical issues such as tripped breakers or corroded wiring. Regular inspection of the sump pit, clearing debris, testing the float action, and verifying wiring and breaker status reduce risk, but mechanical failures still occur unexpectedly during heavy storm cycles. Recognizing these failure modes points directly to why a separate battery backup or redundant pump provides an independent line of defense against flooding.

Common failure causes homeowners should check regularly:

- Motor burnout from age or repeated cycling.

- Float switch obstruction or improper seating.

- Debris–clogged intake or check valve malfunction.

These checks save time and money and lead naturally to the problem of simultaneous power loss during storms.

Failure Analysis of Submersible Pumps: A Comprehensive Review

Submersible pumps are widely employed in various sectors, including domestic use, municipal water supply, irrigation systems, and extensive industrial applications. Consequently, a substantial portion of the total electrical grid energy is consumed by electrical submersible pumps (ESPs). In the event of an ESP malfunction, overall grid energy consumption escalates. Understanding the diverse failure mechanisms inherent in ESPs, identifying their root causes, and implementing appropriate mitigation strategies are crucial for the economic development of any nation. Despite their long history of use, ESPs continue to experience numerous failures, which can be broadly categorized into three main types: electrical, mechanical, and operational failures.

Failure Analysis of Submersible Pumps—A Review, SP Bhore, 2022

How Do Power Outages Impact Sump Pump Reliability?

Power outages frequently coincide with the highest demand on a sump pump—intense rain or storm events—creating a high–risk window for basement flooding. An AC–only sump pump stops immediately when the breaker trips or when grid power fails, leaving any inflow to accumulate rapidly in the pit and then the basement. A battery backup system shifts power automatically to the backup pump or inverter, maintaining pump operation for the duration of the outage or until inflow subsides, and run–time planning must match expected storm durations and inflow rates. Understanding how long a backup must run depends on pump draw and battery amp–hours, which we explain later to help you size an adequate system.

What Are the Financial Risks of Basement Flooding Without Backup?

Basement flooding produces direct repair costs for structural damage, electrical replacement, and flooring as well as indirect costs from mold remediation, ruined personal property, and temporary relocation. Average basement flood claims and remediation expenses can run into the thousands, and mold issues escalate long–term health and repair expenditures if not addressed quickly. Investing in a backup pump is an insurance–style mitigation that reduces expected loss and claim friction; comparing the avoided damage cost to the system investment reveals a straightforward ROI argument for many homeowners. The next section outlines exactly how battery backups operate so you can assess performance versus cost.

How Does a Battery Backup Sump Pump Work?

A battery backup sump pump system works by detecting high water via a float or electronic sensor and switching power from grid AC to a battery source to keep pumping until normal conditions return. The system typically includes a secondary pump (submersible or pedestal), a deep–cycle battery, a charger/maintainer, an automatic transfer mechanism or inverter, and an alarm or monitoring module that alerts owners to activation or low battery. Efficiency and runtime depend on battery AH capacity and pump amperage draw; matching these metrics gives predictable hours of operation in an outage. The following subsections unpack float switch roles, transfer methods, and pump style differences so homeowners can choose compatible components.

What Is the Role of the Float Switch in Pump Activation?

The float switch is the water–level sensor that initiates pump operation when the sump pit reaches a preset height, and its design strongly affects reliability and maintenance needs. Tethered floats pivot on a cord and are simple but can jam on pit walls or debris; vertical floats slide on a stem and offer stable repeatable actuation; electronic level sensors remove moving parts but require different wiring and calibration. Inspect float movement during seasonal checks and consider dual–switch setups that use a primary and redundant sensor for greater resilience. Proper float selection and placement minimize false trips and ensure prompt activation during high inflow events.

How Does Power Transfer Occur During an Outage?

Power transfer during an outage may occur via a dedicated automatic transfer switch, a DC–direct connection to a pump designed for battery voltage, or an inverter that converts battery DC to AC for standard pumps. Automatic transfer devices detect loss of AC and either route battery output to a DC compatible backup pump or power an inverter to run the existing AC pump, with trade–offs in conversion losses and efficiency. DC–direct systems avoid inverter losses but require pumps rated for DC, while inverter systems offer compatibility with existing AC pumps at some efficiency cost. The charger/maintainer also manages battery state of charge before and after outages to preserve lifespan and readiness.

What Are the Differences Between Submersible and Pedestal Pumps?

Submersible pumps sit in the sump pit with the motor sealed for quiet, high–capacity operation, while pedestal pumps have the motor mounted above the pit with a long shaft to the impeller, making them easier to service but noisier. Submersible units usually provide higher GPH rates and are preferred where capacity and quiet operation matter, whereas pedestal pumps work well in shallow pits or where access for maintenance is a priority. Compatibility with backup power varies: many submersibles are more power–hungry, requiring larger batteries or inverters, while some pedestal types have lower draw suited to smaller battery setups. Choosing between them depends on pit dimensions, noise tolerance, capacity needs, and battery sizing considerations explained in later sections.

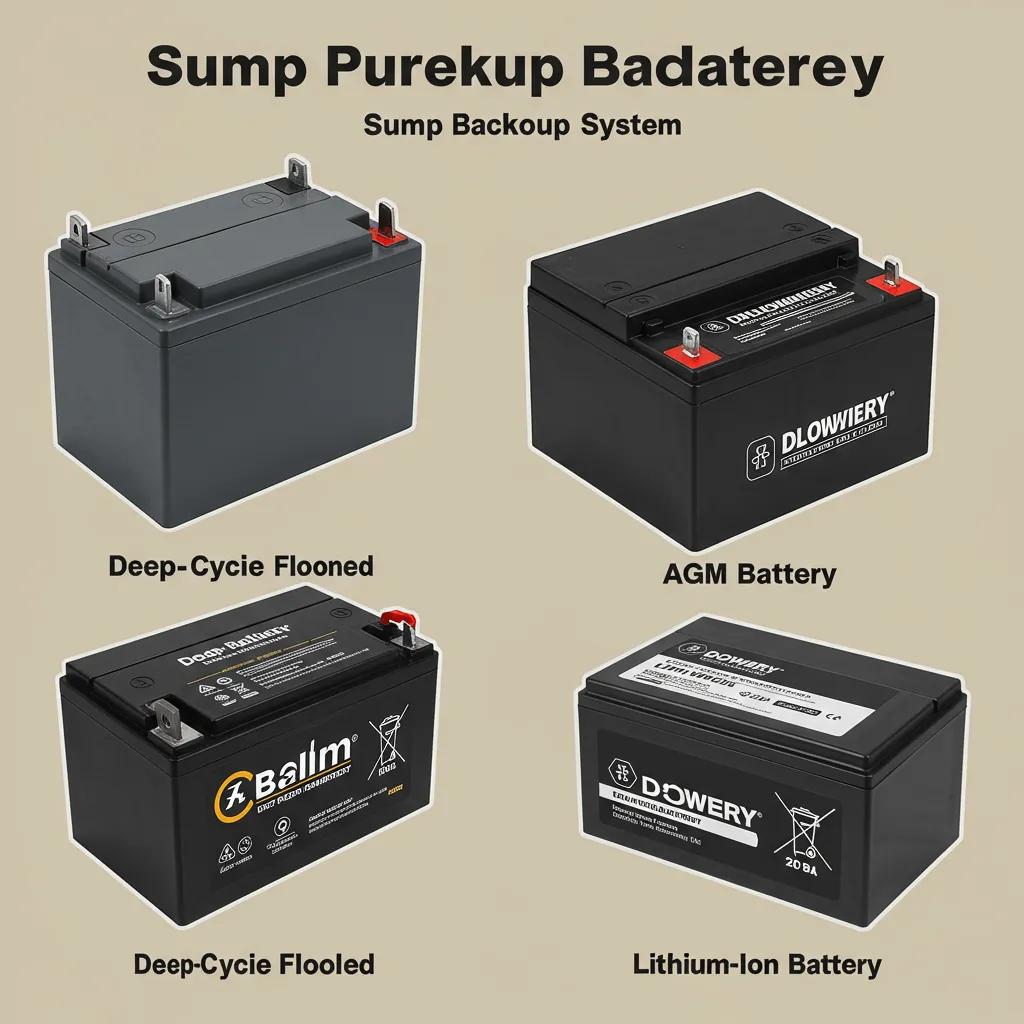

Which Battery Types Are Best for Sump Pump Backup Systems?

Choosing the right battery chemistry impacts runtime, maintenance requirements, safety, and total cost of ownership for a backup sump pump system. Homeowners typically select from deep–cycle flooded wet cell, sealed AGM (absorbed glass mat), or lithium options such as LiFePO4, each with distinct lifespan, maintenance, and safety profiles. The table below compares lifespan, maintenance, cost, runtime per AH, and safety considerations to clarify tradeoffs. After the table, each chemistry is summarized with recommended homeowner scenarios.

Different battery chemistries fit different homeowner priorities: cost minimization, low maintenance, or long lifecycle investment.

| Battery Type | Key Attributes | Typical Lifespan |

|---|---|---|

| Deep–cycle flooded (wet cell) | Lower upfront cost, requires periodic water top–ups and ventilation | 3–5 years with regular maintenance |

| AGM (sealed lead–acid) | Sealed, maintenance–free, moderate cost, tolerant of float charging | 4–7 years depending on cycles |

| LiFePO4 (lithium–iron–phosphate) | Higher upfront cost, long cycle life, lighter, deeper discharge tolerance | 8–15+ years with proper management |

This comparison shows that wet cells lower initial spend while AGMs simplify maintenance and LiFePO4s reduce lifecycle replacement needs; choose based on budget and willingness to perform upkeep.

What Are the Pros and Cons of Deep-Cycle Wet Cell Batteries?

Deep–cycle wet cell batteries offer low upfront cost and familiar technology but require regular maintenance that includes checking water levels and ensuring proper venting for off–gassing. They are sensitive to deep discharges and can have shorter lifespans if frequently cycled deeply, making them less ideal for frequent outage regions without careful management. Wet cells have clear recycling pathways but must be handled as hazardous waste at end of life and stored upright to avoid leaks. For homeowners seeking budget solutions and willing to perform seasonal maintenance, wet cell remains viable but plan for more frequent replacement cycles compared with sealed options.

How Do AGM Batteries Compare in Lifespan and Maintenance?

AGM batteries are sealed lead–acid types that eliminate water top–ups, making them low–maintenance and safer for indoor installation near a sump pit. They tolerate float charging well and typically last longer than flooded wet cells when used as standby backup, offering a strong middle ground between cost and lifecycle. AGMs cost more upfront than wet cells but avoid the same maintenance burden, and their sealed design reduces spill and corrosion risks in basement environments. For typical homeowners who want a set–and–forget solution with predictable replacement intervals, AGM is often the recommended compromise.

Are Lithium-Ion Batteries Suitable for Sump Pump Backup?

Lithium–ion, specifically LiFePO4 chemistry, provides the best lifecycle economics for many homeowners due to high cycle life, ability to use deep discharge without cell damage, and lighter weight for easier placement and handling. LiFePO4 units deliver more usable AH per nominal capacity, require compatible charge management, and often include built–in battery management systems for safety and longevity. The higher initial cost is offset over time by fewer replacements and superior performance in cold temperatures, but ensure your charger and inverter are compatible with lithium charging profiles. Advanced practitioners and homeowners prepared to invest in long–term reliability often choose LiFePO4 for mission–critical backup systems.

What Are the Environmental Impacts and Disposal Considerations?

Batteries carry distinct end–of–life handling requirements: flooded lead–acid batteries are recyclable but require sealed transport; AGM also recycles through lead–acid streams; lithium must be processed at facilities equipped for rechargeable lithium chemistries. Proper disposal reduces environmental hazards from heavy metals and electrolytes, and many retailers or recycling centers accept used batteries for safe processing. Choosing longer–lasting chemistries like LiFePO4 lowers total environmental impact by reducing replacement frequency, and enrolling in manufacturer take–back or community recycling programs helps ensure responsible disposal. After understanding battery types and impacts, the next section explains which system features matter most when selecting a backup.

What Key Features Should You Consider When Choosing a Battery Backup Sump Pump?

Selecting a battery backup sump pump requires matching performance specs—GPH, pump amperage, and battery AH—to your pit inflow and desired runtime, while also evaluating charger amperage, alarms, monitoring, and warranty coverage. Look for systems that clearly state pump draw (amps), rated GPH at given head heights, charger float current, and alarm/monitoring options, because those numbers determine how long a backup will actually run under expected conditions. The table below translates system features into homeowner–oriented recommended specs so you can quickly compare options based on typical basements and risk tolerances.

When reviewing features, prioritize runtime calculations and reliable alerting so you know when the backup engages or when battery health declines.

| System Feature | Why it matters | Recommended homeowner spec |

|---|---|---|

| Pump GPH & Amps | Determines water removal rate and battery draw | Match pump GPH to peak inflow; confirm amps for AH calc |

| Battery AH rating | Dictates run–time under load | Size to provide several hours at expected pump draw |

| Charger amps | Affects recharge speed and float maintenance | 1–5 A float chargers common; higher amps shorten recharge |

| Alarm & monitoring | Provides activation and low–battery alerts | Audible + remote push or SMS notifications recommended |

| Warranty terms | Defines coverage for pump and electronics | Clear separate warranties for pump and battery preferred |

This feature checklist helps you focus on the specs that produce predictable performance and long–term reliability.

How Important Are Gallons Per Hour and Amp-Hours Ratings?

GPH and AH are the two core metrics to determine backup effectiveness: GPH measures how much water the pump moves per hour while AH measures how much energy the battery stores. A simple runtime estimate uses pump amperage and battery AH: Runtime (hours) ≈ Battery AH × Battery Voltage ÷ Pump Amps ÷ Inverter Efficiency (if used). For example, a 12 V battery with 100 AH powering a 3 A DC pump yields roughly 12×100×3 ≈ 400 Wh/ (3 A × 12 V) → about 33 hours of theoretical DC runtime; practical factors reduce this number, so always include safety margins. Accurately calculating these numbers ensures you select a battery and pump pair that meet storm–duration needs rather than relying on manufacturer runtime claims alone.

Quick estimation checklist:

- Record pump amperage at operating head.

- Multiply battery AH by voltage to get Wh.

- Divide Wh by pump watt draw and adjust for inverter losses.

Knowing runtime helps choose whether a single battery or battery bank is necessary.

What Smart Monitoring and Alarm Features Are Available?

Modern backup systems offer audible alarms, visual indicators, and smart monitoring modules that send push notifications or emails when the backup activates, battery voltage drops, or a self–test fails. Remote alerts are especially valuable when homeowners are away or elderly occupants cannot react quickly; a monitored system dramatically reduces response time and potential damage. Self–test and diagnostic logs also alert you to declining battery health before an outage, allowing proactive replacement and preserving system readiness. Prioritize systems with clear notification pathways and simple user interfaces so you receive actionable alerts without false alarms.

How Do Charger Amps and Warranty Affect System Reliability?

Charger amp rating determines how quickly a depleted battery returns to float charge and how effectively the charger maintains battery health over months of standby. Undersized chargers can extend recharge time after long outages and may allow sulfation on lead–acid cells, while appropriately sized float chargers maintain charge without overcharging. Warranty coverage matters because battery, pump, and electronics often have separate terms; understanding what is covered and for how long prevents surprise costs, so look for explicit warranty durations and conditions. Aligning charger specs and warranty terms with your maintenance plan ensures reliable operation and predictable lifecycle costs.

How Much Does a Battery Backup Sump Pump System Cost?

Battery backup sump pump system cost varies widely based on components: a basic battery kit with small sealed battery and simple backup pump differs from a premium lithium system with integrated smart monitoring and professional installation. Typical equipment ranges and installation costs can be grouped into low/typical/high tiers shown in the table below, which helps homeowners set realistic budgets and compare long–term costs versus expected avoided damage. After the table we break down installation factors, maintenance, and an ROI example.

Reviewing cost components clarifies where upfront investments reduce recurring replacement expenses.

| Cost Item | Typical Range | Notes |

|---|---|---|

| Basic backup kit (equipment only) | $200–$600 | Small sealed batteries, basic alarms |

| Mid–range system (AGM, better pump) | $600–$1,500 | Improved runtime, sealed batteries, alarms |

| Premium system (LiFePO4, smart monitoring) | $1,500–$4,000+ | Long lifecycle, remote alerts, higher capacity |

| Installation (professional) | $300–$1,200+ | Depends on pit condition, plumbing, permits |

This breakdown shows equipment and installation together determine initial outlay; long–term battery replacements add to lifecycle cost.

What Is the Typical Installation Cost for Battery Backup Systems?

Installation costs depend on pit accessibility, discharge piping complexity, need to replace or relocate the primary pump, and whether electrical or permits are required. Simple installs that attach a battery kit and route discharge to existing piping are on the low end, while reconfiguring discharge lines, adding check valves, or installing inside conditioned spaces increases labor and materials. Professional installation is recommended when pit size is constrained, when local codes require licensed work, or when you want an optimized battery bank and smart monitoring integration. Considering these factors helps you decide between DIY approaches for simple kits and pro installs for complex or code–sensitive situations.

How Do Long-Term Maintenance and Battery Replacement Affect Cost?

Long–term costs include periodic battery replacement (every 3–15 years depending on chemistry), occasional pump servicing or replacement, and routine checks and charger replacement as needed. Annualized budgeting—spreading replacement costs over expected life—gives realistic yearly ownership costs: for example, an AGM replaced every 6 years vs a LiFePO4 replaced every 12+ years will produce distinct annualized costs despite different upfront prices. Regular maintenance and proper charging regimes extend battery life and reduce total ownership cost, making lifecycle math essential for evaluating options rather than only comparing sticker prices.

After considering long–term costs, many homeowners opt to get a tailored estimate and installation plan to ensure capacity and runtime match their specific risk profile; if that describes you, please request a free consultation or service.

What Are the Insurance and ROI Benefits of Installing Backup Pumps?

Installing a backup pump reduces the likelihood of filing a flood claim and can demonstrate to insurers that you’ve materially reduced risk, which may improve claim outcomes and in some cases qualify you for premium consideration. ROI can be framed simply: compare the expected avoided damage cost (probability of flooding × average claim size) against system and maintenance expense; even a single avoided severe flood often justifies a moderate backup investment. Documenting the installed system and keeping maintenance records maximizes your ability to show risk mitigation to insurers and recover value from the investment. After weighing these insurance and ROI factors, it’s often practical to choose a system sized for worst–case storm durations and then document installation for your insurer—if you want personalized help to calculate ROI and sizing, request a free consultation or service.

How Do You Install and Maintain a Battery Backup Sump Pump System?

Installation and maintenance decisions balance safety, code compliance, and long–term readiness; professional installation lowers risk from improper wiring, poor discharge routing, or incompatible charging setups, while DIY can be viable for experienced homeowners on simpler systems. A proper installation includes correct battery placement, secure wiring, a charger/float setup matched to the battery chemistry, and reliable discharge routing with a functioning check valve to prevent backflow. Maintenance involves periodic inspections, float tests, battery health checks, and seasonal drill runs to ensure the backup activates and the alarm functions. The next subsections help you decide when to hire a pro, how to extend battery life, and basic troubleshooting steps.

Should You Choose Professional Installation or DIY?

Professional installation is recommended when local electrical or plumbing codes apply, when the sump or discharge needs modification, or when using high–capacity battery banks or lithium chemistry that require specific charger profiles and safety measures. DIY can work for competent homeowners installing a packaged backup kit with sealed lead–acid batteries and clear instructions, but consider that warranties or insurance documentation may require licensed installation in some areas. Safety considerations—battery ventilation for flooded cells, proper wiring, and secure mounting—favor professional service if you lack electrical experience. If you choose DIY, follow manufacturer guidance, test thoroughly, and keep detailed records of procedure and parts.

Decision checklist for hiring a professional:

- Complex pit or discharge plumbing required.

- Use of lithium batteries or battery banks.

- Local permit or code requirements apply.

Choosing appropriately reduces risk and preserves warranty coverage.

What Are the Best Practices for Maximizing Battery Lifespan?

Maximize battery lifespan by avoiding deep discharges, maintaining correct float charging, controlling ambient temperature where the battery is stored, and performing regular load tests and visual inspections. For lead–acid types, keep terminals clean and ensure proper ventilation for flooded cells; for AGM and lithium, verify compatible charger profiles and avoid prolonged high–temperature exposure. Schedule a quarterly visual and functional check and an annual capacity test to detect declining performance before storms hit. These practices reduce unexpected failures and extend the time between costly replacements.

How Can You Troubleshoot Common Issues Like Float Switch Failures?

Troubleshoot float switch failures by first visually inspecting for debris or obstructions in the pit that restrict movement, then manually exercising the float to confirm the switch actuates and the pump responds. If the float moves freely but the pump does not start, check breaker and wiring connections, then test battery voltage and charger output; for systems with alarms, consult diagnostic LED codes or logs. Replace worn floats, corroded connectors, or failed check valves promptly, and call a professional if electrical faults or persistent component failures occur. Documenting troubleshooting steps creates a maintenance history helpful for warranty claims or professional service assessments.

Frequently Asked Questions

What maintenance is required for a battery backup sump pump system?

Regular maintenance for a battery backup sump pump system includes inspecting the pump and battery at least once a year. Homeowners should check for debris in the sump pit, test the float switch for proper operation, and ensure that the battery is charged and functioning correctly. Additionally, it’s important to perform load tests on the battery to assess its capacity. Keeping a maintenance log can help track performance and identify any issues early, ensuring the system is ready when needed.

How can I tell if my battery backup sump pump is working properly?

To ensure your battery backup sump pump is functioning correctly, conduct regular tests by simulating a power outage. Disconnect the primary power source and observe if the backup pump activates automatically. Listen for the pump’s operation and check for water removal. Additionally, monitor the battery’s charge level and inspect the alarm system for alerts. Regular testing helps identify potential issues before they lead to failure during an actual outage.

What should I do if my sump pump fails during a storm?

If your sump pump fails during a storm, first check if the backup system activates. If it does not, inspect the float switch, battery charge, and connections for any issues. If the backup system is also non-functional, consider using a manual pump or siphon to remove water until repairs can be made. After the storm, assess the primary pump for damage and perform necessary maintenance or replacements to prevent future failures.

Can I install a battery backup sump pump myself?

Yes, many homeowners can install a battery backup sump pump themselves, especially if they choose a simple kit with clear instructions. However, if your installation involves complex plumbing, electrical work, or local code requirements, hiring a professional is advisable. Proper installation is crucial for safety and system reliability. If you opt for DIY, ensure you follow the manufacturer’s guidelines and keep detailed records of your installation for warranty purposes.

What are the signs that my sump pump battery needs replacement?

Signs that your sump pump battery may need replacement include a significant drop in runtime during tests, visible corrosion on terminals, or a battery age exceeding its expected lifespan. Additionally, if the battery fails to hold a charge or the alarm system indicates low battery status, it’s time to consider a replacement. Regular testing and monitoring can help you catch these issues early, ensuring your backup system remains reliable.

How do I choose the right battery for my sump pump backup system?

Choosing the right battery for your sump pump backup system involves considering factors such as capacity, maintenance requirements, and lifespan. Deep-cycle flooded batteries are cost-effective but require regular maintenance, while AGM batteries offer a balance of performance and low maintenance. Lithium-ion batteries provide the longest lifespan and best performance but come at a higher initial cost. Assess your budget, maintenance preferences, and expected usage to select the best option for your needs.

What should I do with my old sump pump battery?

Old sump pump batteries should be disposed of properly to minimize environmental impact. Many types of batteries, especially lead-acid and lithium-ion, require special handling due to hazardous materials. Check with local recycling centers or waste management facilities for guidelines on battery disposal. Some retailers also offer take-back programs for used batteries. Proper disposal ensures that harmful substances are managed safely and can help recover valuable materials for recycling.

How Long Do Battery Backup Sump Pumps and Their Batteries Last?

Battery backup systems’ lifespans vary: primary pumps often last 7–10 years with proper maintenance, AGM batteries commonly last 4–7 years, flooded wet cells around 3–5 years, and LiFePO4 batteries often last 8–15+ years under appropriate charge management. Regular testing and correct charging extend component life, while frequent deep discharges shorten it; keeping replacement records helps plan budgets. Inspect and test systems annually and replace batteries according to observed capacity, not just age.

Should Every Home Have a Battery Backup Sump Pump?

Not every home requires a battery backup, but it is strongly recommended for properties with finished basements, valuable stored goods, prior flood history, or in regions with frequent storm–related outages. Use a risk checklist—finished space, occupant vulnerability, depth of pit, and regional outage frequency—to decide; high–risk homes should prioritize redundancy. For moderate–risk homes, simpler or temporary solutions may suffice, but permanent backup offers long–term protection and peace of mind.

What Causes Primary Sump Pump Failures and How Can Backup Help?

Primary pump failures most commonly stem from motor burnout, float switch jamming, debris clogging, or loss of power; a properly configured battery backup activates independently of grid power and provides a second pumping path to remove inflow. Backups mitigate both mechanical and electrical failure modes by supplying independent power and sometimes a secondary pump motor. Combining routine maintenance on the primary pump with a reliable backup yields the best defense against basement flooding.

How Do Water–Powered Backup Pumps Compare to Battery Systems?

Water–powered backup pumps use municipal water pressure to create suction and remove sump water without electricity, offering a maintenance–free option where adequate water pressure and code compliance are available. They avoid battery replacement but depend on uninterrupted municipal water supply and may have lower capacity under some conditions, while battery systems offer more flexible placement and predictable runtime if sized correctly. Choose water–powered where municipal pressure and plumbing allow; choose battery backup where electrical independence and higher capacity are priorities.

If you are weighing options or need a tailored sizing, cost, or installation plan based on your basement and risk profile, please request a free consultation or service.

Please request a free consultation or service.

Conclusion

Investing in a battery backup sump pump system is crucial for safeguarding your basement against flooding and power outages, ensuring peace of mind during severe weather. By understanding the mechanics, features, and maintenance of these systems, homeowners can make informed decisions that protect their property and finances. Don’t wait for disaster to strike; take proactive steps to secure your home today. For personalized advice and tailored solutions, please request a free consultation or service.